Welding, which denotes “the permanent joining of components by applying heat or pressure”, has long been part of HA-BE’s spectrum of offers. Besides conventional fusion welding techniques, HA-BE has acquired high expertise in the area of laser welding during the past few years. HA-BE is a certified welding specialist company officially recognised by the German Welding Society DVS ZERT e.V. in accordance with the standards DIN EN 1090-1, DIN-EN 1090-2 and DIN EN ISO 3834-2 :2006.

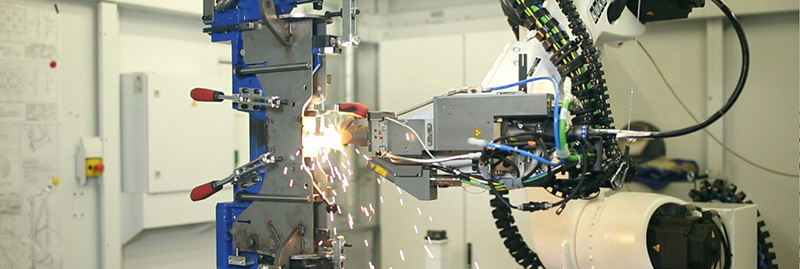

In addition to conventional TIG, MIG and MAG gas-shielded welding processes, HA-BE has extensive expertise in the area of laser welding. State-of-the-art laser welding cells offer significant advantages in terms of speed and major cost benefits: due to the small heat-affected zone, distortion is considerably reduced compared with conventional welding methods.

Laser-welded constructions are more beneficial than conventional ones; the suitability for automation enables reproducible processes of higher quality, which makes time-consuming and costly finishing processes largely unnecessary. These cost effects are complemented by the technical advantages. Deep penetration welding enables the fabrication of load-bearing joints, whereas conduction welding generates surfaces with especially nice and smooth edges. In this way, precision and efficiency linked with aesthetics and durability make a perfect combination.